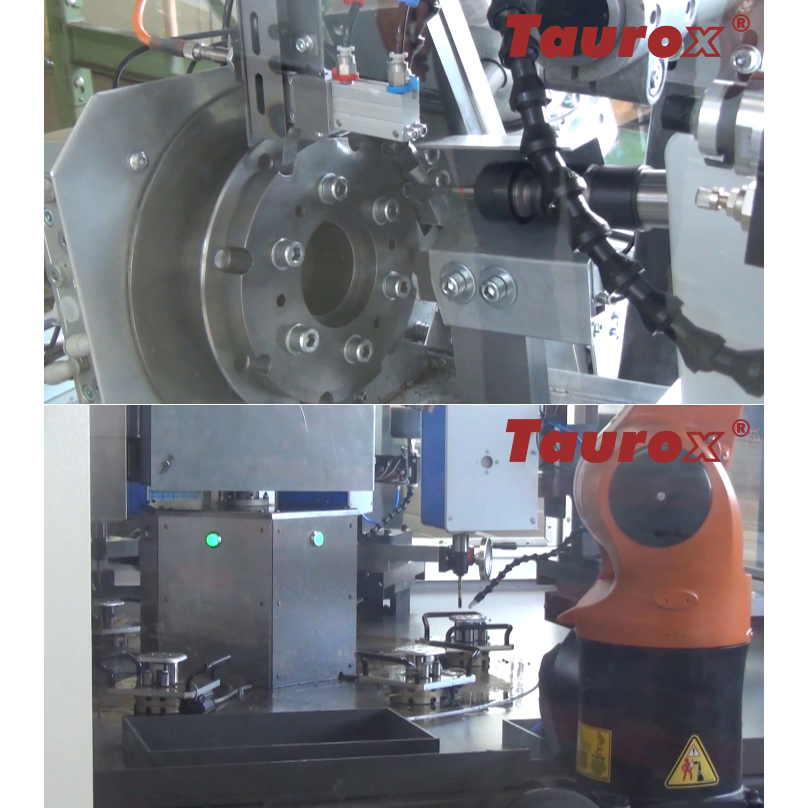

Thread Manufacturing in Automation

Taurox threading units for automated thread manufacturing stand out with seamless quality control, the marking of defective parts, and alerts for worn tools. They also deliver high production volumes thanks to rapid processing and optimized machining parameters. With a built-in PLC interface, these units integrate effortlessly into automation systems. We provide comprehensive support and consulting to help you incorporate our machines into your existing or planned automation setups. Additionally, we can facilitate complete automation solutions in collaboration with our trusted partners.

Connectivity Options of the Taurox Tapping Units

PLC interface

Located on the rear of the drive unit, the PLC interface enables seamless integration of the tapping unit into automated systems. This interface allows for external initiation of machining processes while providing real-time status updates and quality data for reliable process monitoring.

Your benefits at a glance:

- Easy integration:

Standardized 24V inputs allow reliable connection of start signals from PLCs or robot controllers. - Process control:

Multiple outputs provide status signals (e.g., “in operation,” “process complete,” “fault”) that can be directly incorporated into higher-level control systems. - Quality assurance:

Automatic feedback on the last operation (e.g., OK/NOK signals) supports seamless quality monitoring and enables immediate rejection of defective parts. - Flexible peripheral control:

Interfaces for external devices such as signal towers, lubrication systems, or air blast units ensure optimal adaptation to individual production processes. - Robust and reliable:

Short-circuit-proof 24V control signals guarantee trouble-free operation even in demanding industrial environments.

This versatile interface provides maximum flexibility for your automation solutions, ensuring smooth, safe production—perfect for use in automated manufacturing cells and production lines.

Modbus TCP

The Taurox tapping unit enables reliable communication with automation systems via Modbus TCP through its Ethernet interface. Key features include:

- Setting machining parameters:

- Loading new parameter sets (e.g., machining speed, machining depth)

- Defining the workpiece zero point

- Retrieving machine information:

- Machine operating status

- Error codes

- Quality of the last operation

- Currently active machining parameters

- Current and maximum machining depth

- Torque from the last operation

- Flexible customization:

- Customer-specific Modbus protocol extensions available on request

This interface ensures seamless integration into existing production lines and provides complete transparency of the machining process.

Cycle Time Reduction through Parameter Optimization

Taurox tapping units are specifically designed for maximum speed and efficiency in automated manufacturing processes. Several features contribute significantly to reducing cycle times:

- High processing speed:

Accelerates the actual tapping process, significantly reducing the machining time per workpiece. - Increased return speed:

Minimizes spindle dwell time inside the workpiece, speeds up the return stroke, and shortens the overall cycle time. - Activation of release height:

The release height is a relative distance above the workpiece surface, allowing the automation system to position the next workpiece while the spindle is still returning. With fast part placement, the next machining process can even begin before the spindle reaches its upper end position. - Adjustable feed rate:

The spindle’s feed rate can be individually adjusted and optimized to further reduce machining time.

Special advantage of the release height with long feed paths

A particular benefit of the release height becomes apparent with workpieces requiring a relatively long feed path, such as complex geometries or multiple threads with different zero points. In these cases, early release of the workpiece enables:

- Significant reduction of non-productive time over long travel distances

- Parallel placement and alignment of the next workpiece during spindle movement

- Optimal cycle times even with variable workpiece positions

By combining these features, Taurox tapping units make a crucial contribution to increasing efficiency and optimizing cycle times in automated series production.