Accessories for thread tapping machines and units

We provide suitable accessories for your applications. Costum-made products and adaptions are available at short notice.

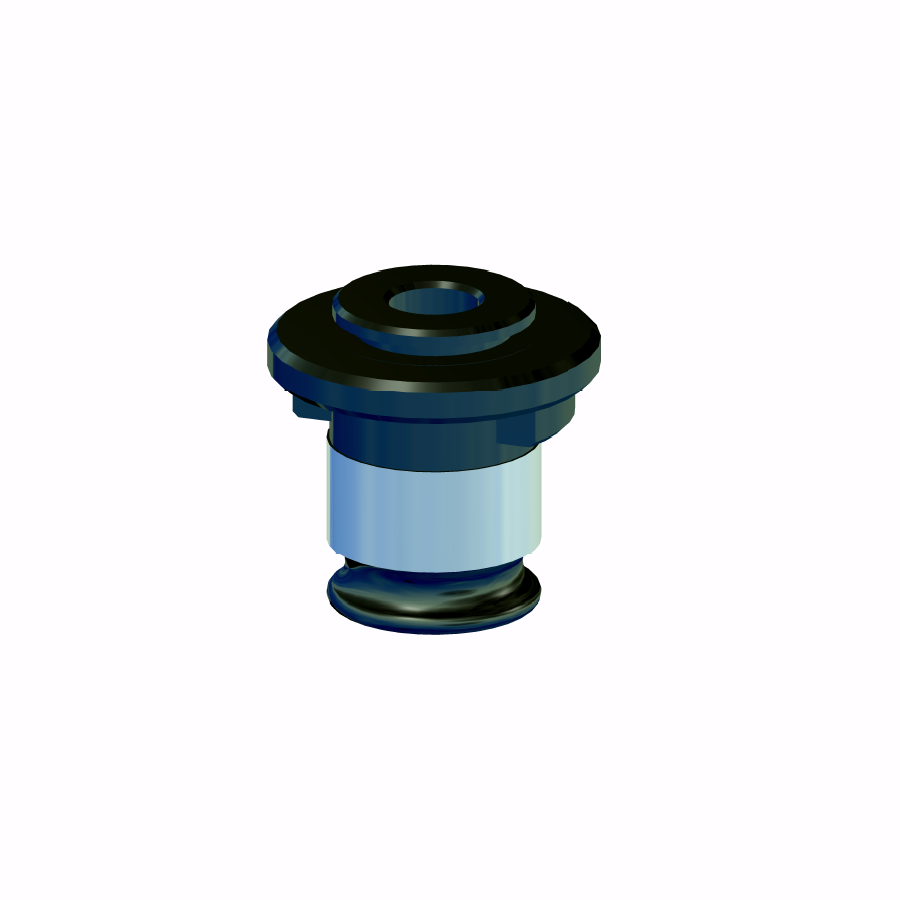

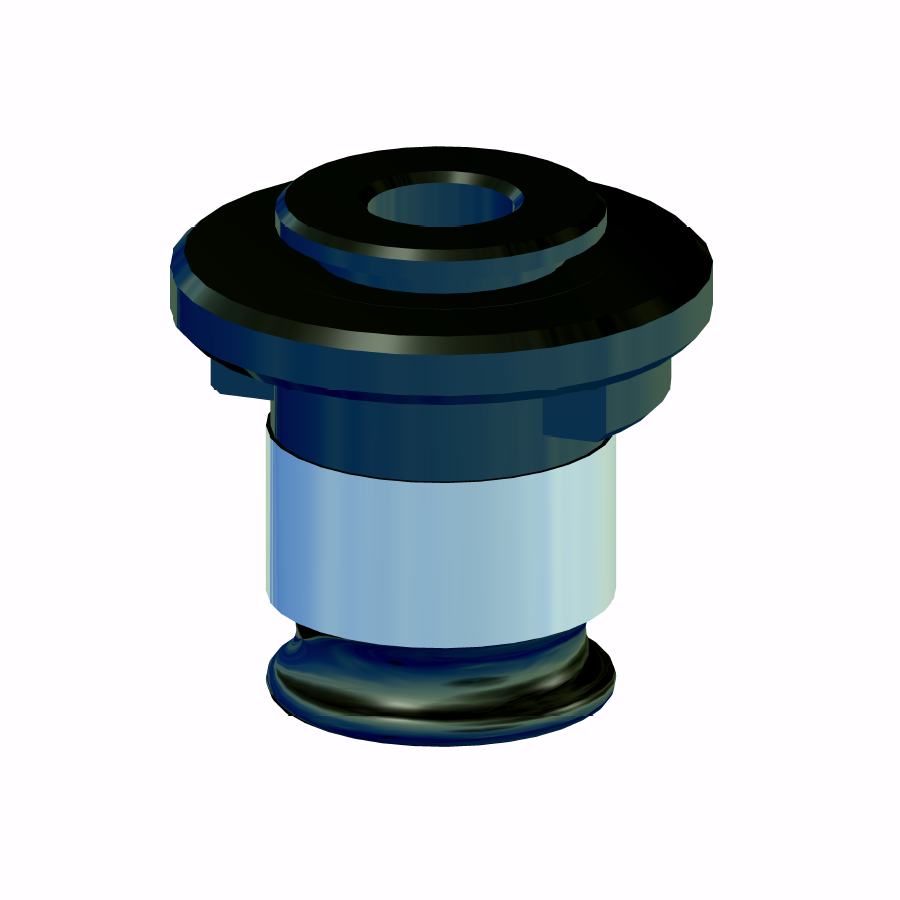

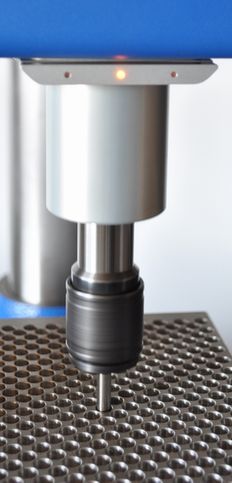

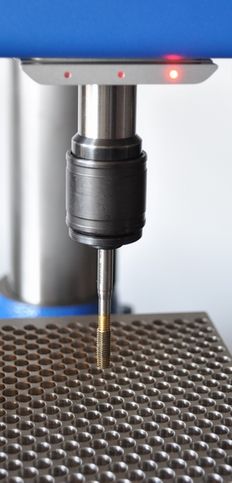

Quick change inserts size 0 - 2

To mount taps in quick change tapping chucks.

The selection of the taps results out of shank diameter and square.

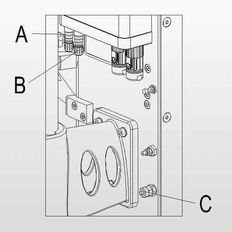

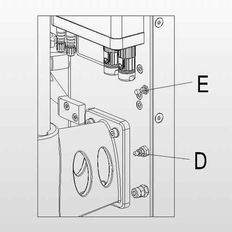

Feed system for spindle

The feed is especially well suited for handling solutions and automation

- steplessly adjustable limit for gating force with presentation in display

- steplessly adjustable speed of feed

- damping for low tool wear

- start by foot switch, sensor, or PLC interface (accessory)

- start on adjustable release height (time saving)

- pneumatic 58 - 116 psi / 4 - 8 bar

Foot switch, proximity switch for feed system

- foot switch in standard design

- foot switch in robust design

- inductive proximity switch with plug

Minimum lubricant unit 2V with lubricant pulse and air pulse

- pneumatic 58 - 87 psi / 4 - 6 bar

- adjustable dosage in the microliter range

- 2 vent to control

- without spray mist

- time and pulse adjustable by user interface unit

- Swap body with quick release makes it easier to fill the container

- very low usage of cooling lubricant

Minimum lubricant unit 3V with lubricant pulse, air pulse and air cleaning pulse

- pneumatic 58 - 87 psi / 4 - 6 bar

- adjustable dosage in the microliter range

- 3 vents for separate control

- without spray mist

- time and pulse adjustable by user interface unit

- Swap body with quick release makes it easier to fill the container

- very low usage of cooling lubricant

- the final blow cleans after work process

- final blow control at the chip cleaning work mode

Signalbar for quality evaluation

The signal Bar is used for visual quality evaluation for the operator.

In combination with the piece counter, the Control Survey will require a confirmation by the user whether to stop or continue the operation in case of error.

- green, yellow, red

- green means: Quality good, work process without errors

- yellowe means: Machine is working

- red means: Errors occurred during work process

Signal light column for quality evaluation

- green, yellow, red and horn

- green means: Quality good, work process without errors

- yellow means: Machine is working

- red and horn (short signal) means: Errors occurred during work process

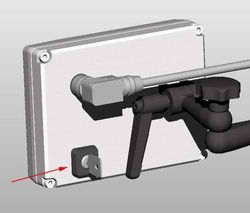

Key switch with lock-out

- locks the user interface

- locks the output signal of the clamping function in case of errors during work process

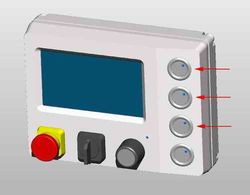

Additional push buttons selection for parameter data base

- direct access to saved parameter sets

- fast switch of tool

- assigning special functions (on demand)