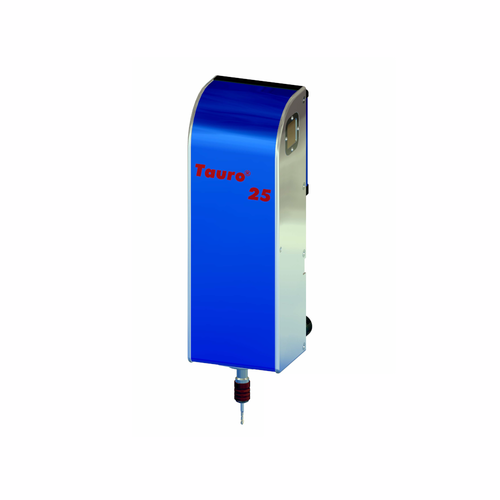

Tauro 25E M1 - M6 thread tapping unit

The Tauro 25E thread cutting unit was designed for efficient series production up to M6. Its flexible connection options and reliable process monitoring system ensure safe and continuous operation in automated production environments.

Technical data

| Thread capacity thread cutting (AlMg4.5Mn / 3.3547) |

M1 – M6; blind hole 2.0 x D |

| Thread capacity thread cutting (X6CrNiMoTi17–12–2 / 1.4571 / V4A) |

M1 – M5; blind hole 1.5 x D |

| Torque range adjustable | 0.10 - 2.50 Nm |

| Speed range adjustable | 50 – 3000 rpm |

| Spindle feed system | pneumatic with monitoring |

| Spindle / tool holder | quick change holder Size 0 |

| Dimensions / Weight drive unit | 164 x 165 x 490 mm WxDxH / 9.8 kg |

| Dimensions / Weight control unit | 400 x 300 x 120 mm WxDxH / 8.2 kg |

| Dimensions / Weight operating panel | 166 x 43 x 124 mm WxDxH / 1 kg |

| Electric supply / Power input | 230 V~ / 615 W |

| Power input non-operated | < 40 W |

| Cable length between the modules | 2 m (special line up to 12 m) |

| Usage situation | vertical (accessories: horizontal) |

| Spindle travel / thread depth | 90 / 80 mm |

| Depth accuracy | 0.1 mm |

| Digital inputs | 3 (24 V) |

| Digital outputs | 10 (24 V / 3.6 W) short-circuit proof |

| Connector for inputs and outputs | Included in delivery |

| Ethernet interface | Included in delivery |