Tapping Units for Seamless Integration into Industrial Automation

Our tapping units are specifically designed for seamless integration into industrial automation systems. They deliver the same high performance, user-friendliness, and precision as our proven standalone tapping machines—just without the column, base, or mounting flange. Ideal for space-saving installation directly into your production line.

A pneumatic feed and PLC interface come as standard, ensuring smooth and efficient automation.

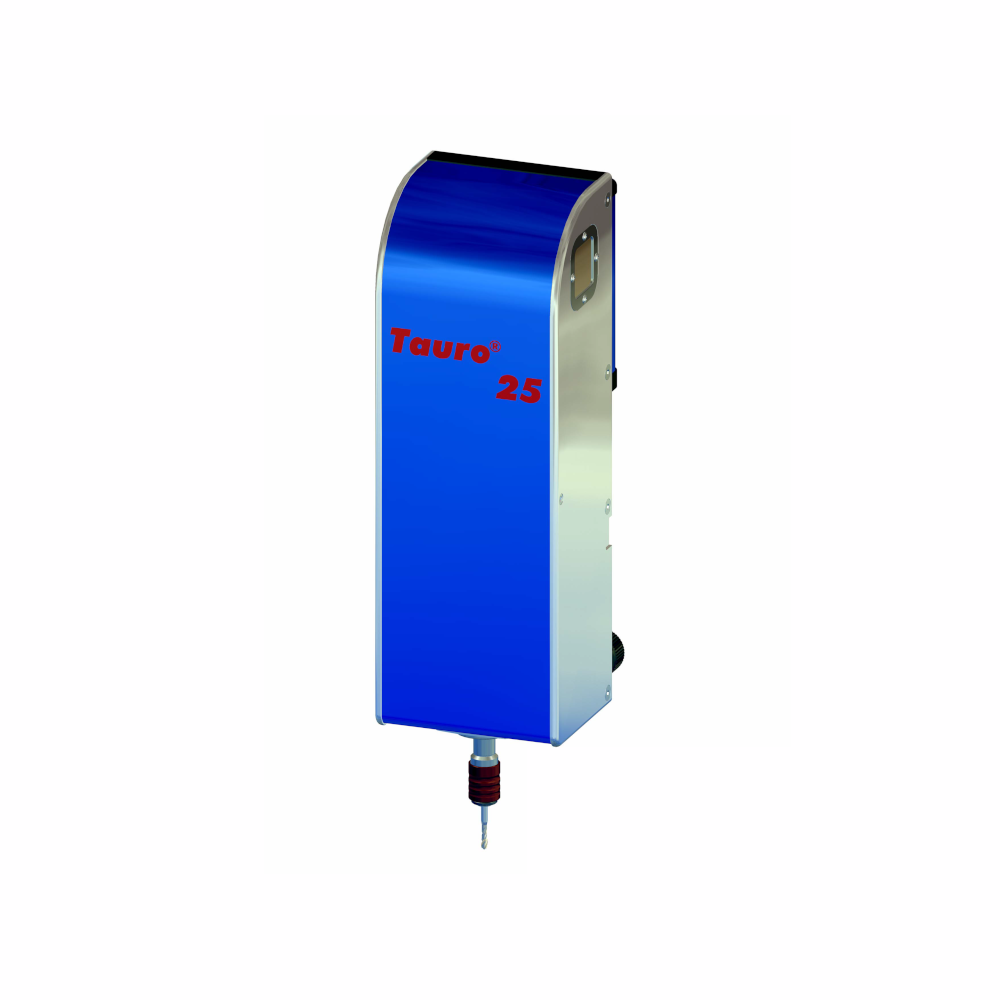

Tauro 8E - 120E M0.5 - M12

Thanks to a direct drive, the Tauro 8E to 120E product series is characterized by very sensitive torque monitoring, low inertia of the spindle and excellent tool breakage prevention, which allows for a very wide range of threading tool sizes to be used.

Taurox 300E - 900E M4 - M22

The Taurox 300E to 900E series achieve high torques for machining particularly large threads with a step-up gear, despite its low power consumption. Accurate torque monitoring and effective tool breakage prevention are a matter of course for a Taurox product.

Flexible Expansion – Accessories for Optimal Integration

Taurox tapping units can be precisely adapted to your production environment with a range of practical accessories. Whether it’s specialized clamping technology for complex workpieces, minimum quantity lubrication systems for clean and resource-efficient machining, or custom mounting solutions—each accessory is designed to support the seamless integration of the unit into your automation process.

Additionally, the TauroView software offers valuable functions for optimizing machining parameters and selecting the appropriate tool and lubricant.