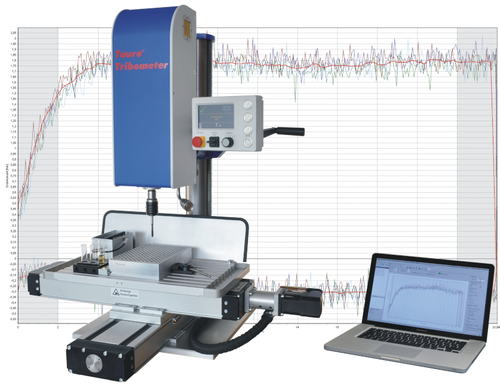

Tauro Tribometer Tapping Torque Test System

The Tauro Tribometer is a test system for evaluation of friction and wear at cutting and forming thread tapping. The analysis software TauroLink allows for recording of measurement data, graphical representation of torque curves, statistical analysis and comparison of test objects. The test system is designed for optimization of cooling lubricants, lube oils, fine tuning lubricant additives and improvement of tool geometry and coating. With a high precision XY coordinate table, test bores are positioned automatically and accurate. An optional cleaning station provides the automatic tool cleaning between measurements.

Optimized for the Tauro Tribometer, our partner Microtap USA Inc. has developed a new international ASTM standard:

ASTM D8288 - 19 "Standard Test Method for Comparison of Metalworking Fluids Using a Tapping Torque Test Machine" that has been officially approved in January 2020.

Please contact us to receive additional information Request for information

Take advantage and get your lubricants evaluated by using our service tribological tests to get an idea of the quality and significance of the test results.

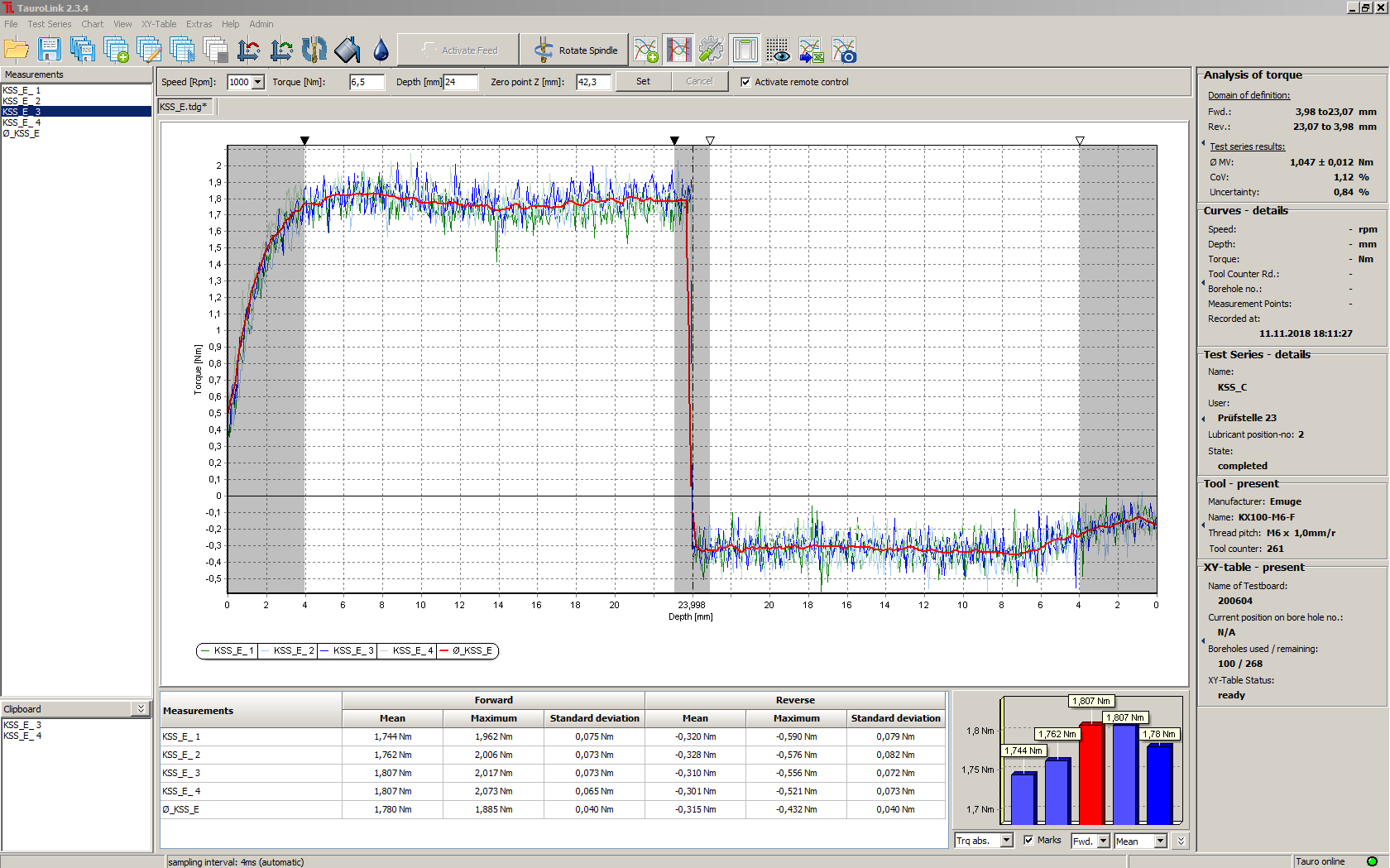

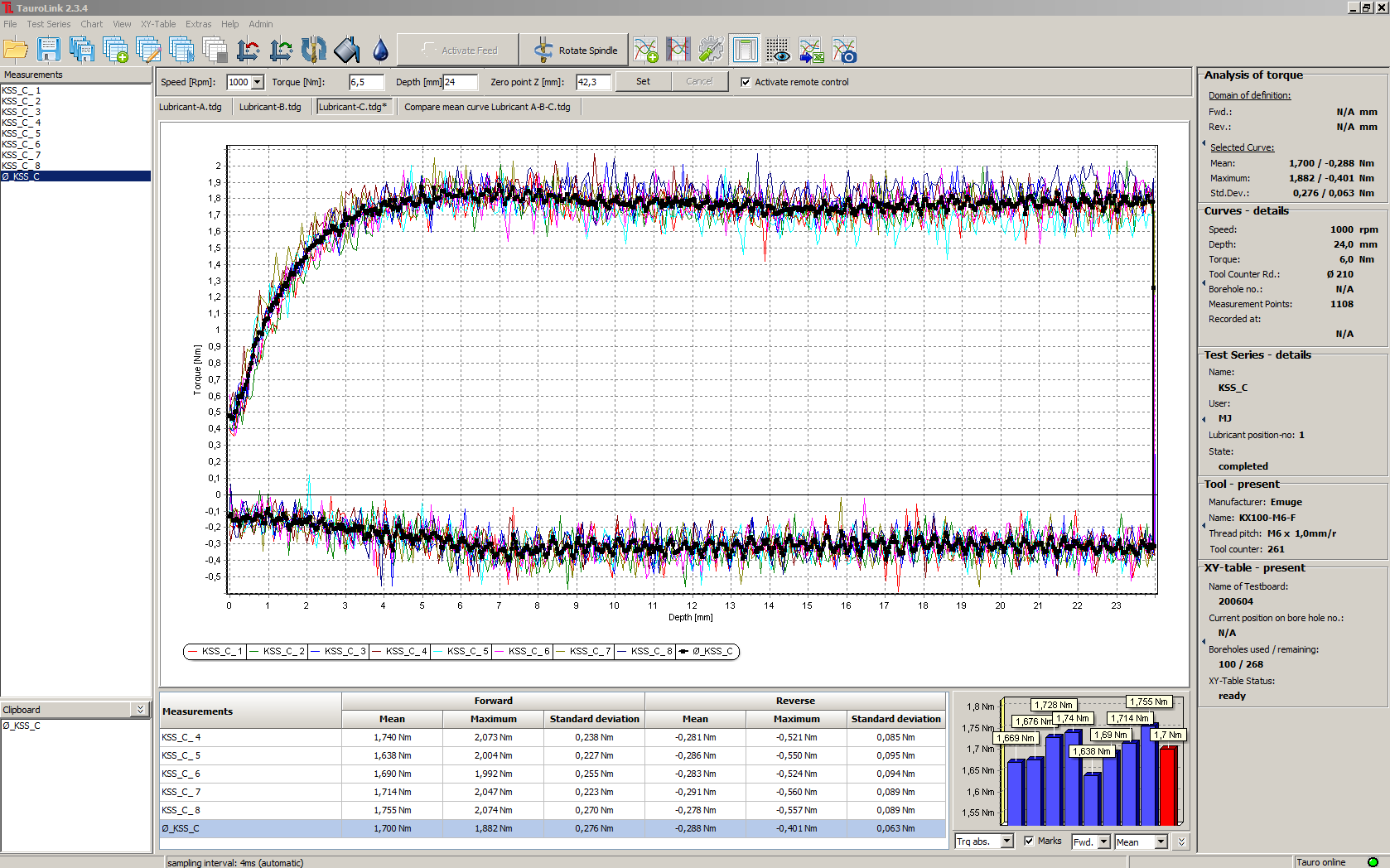

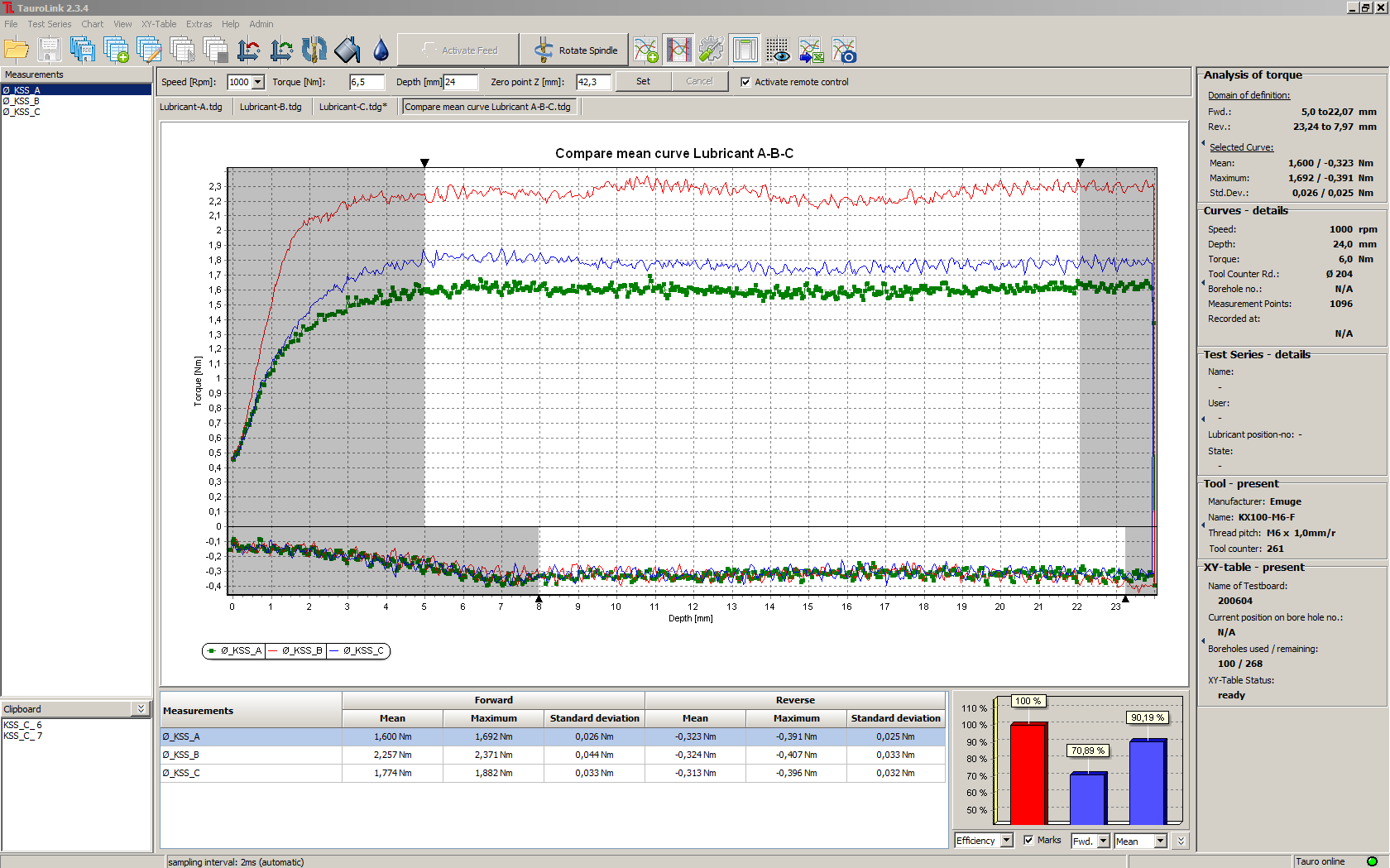

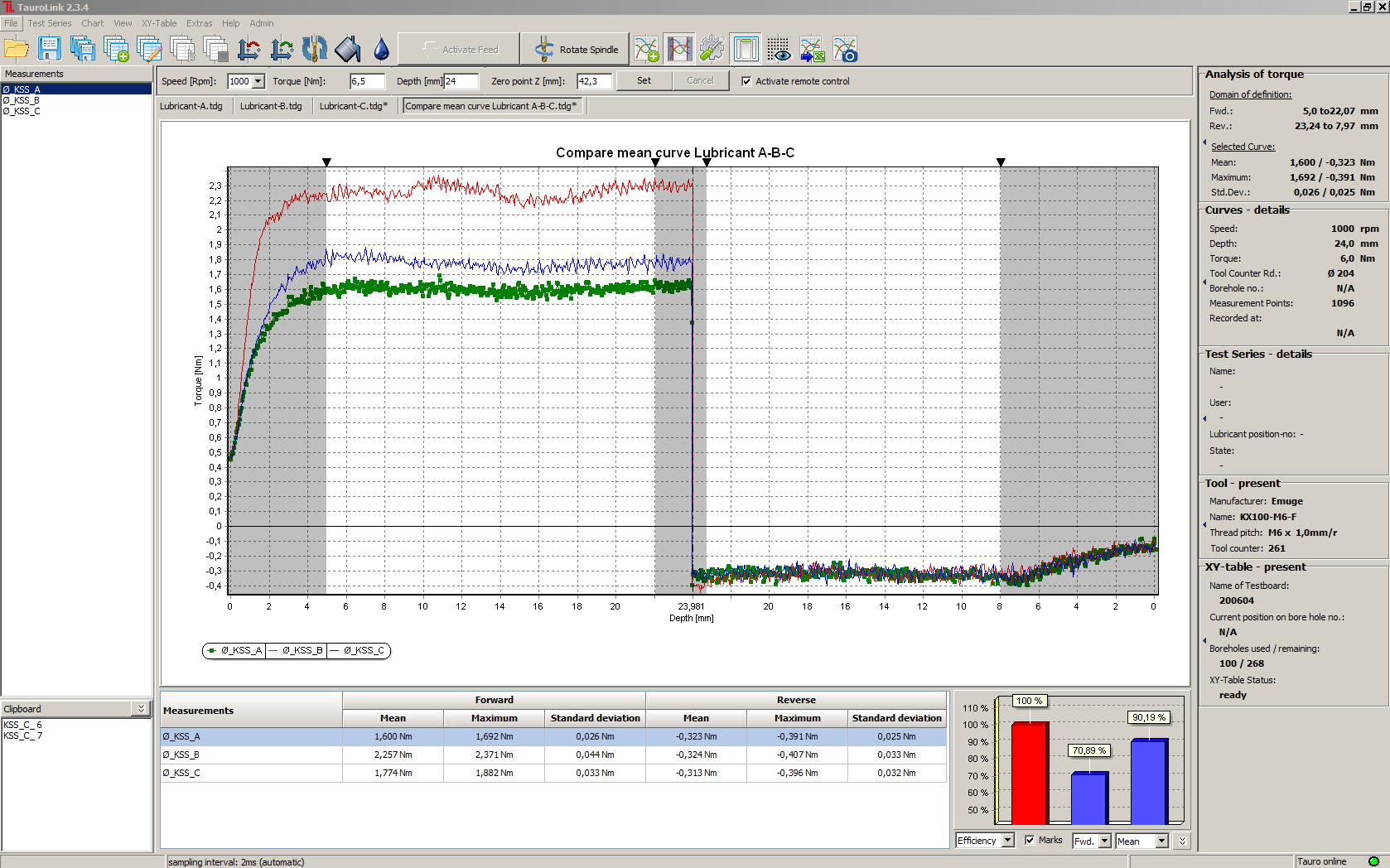

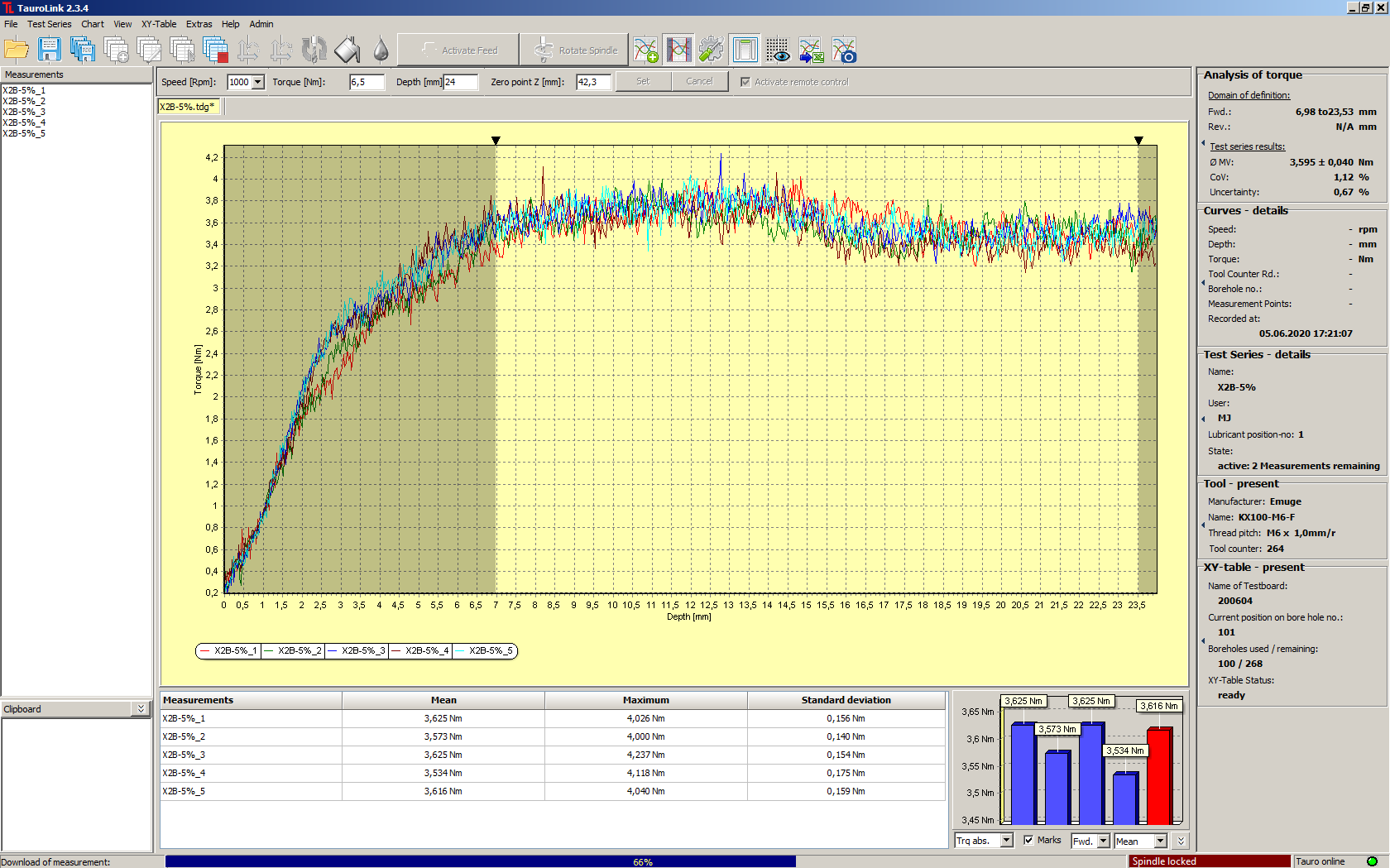

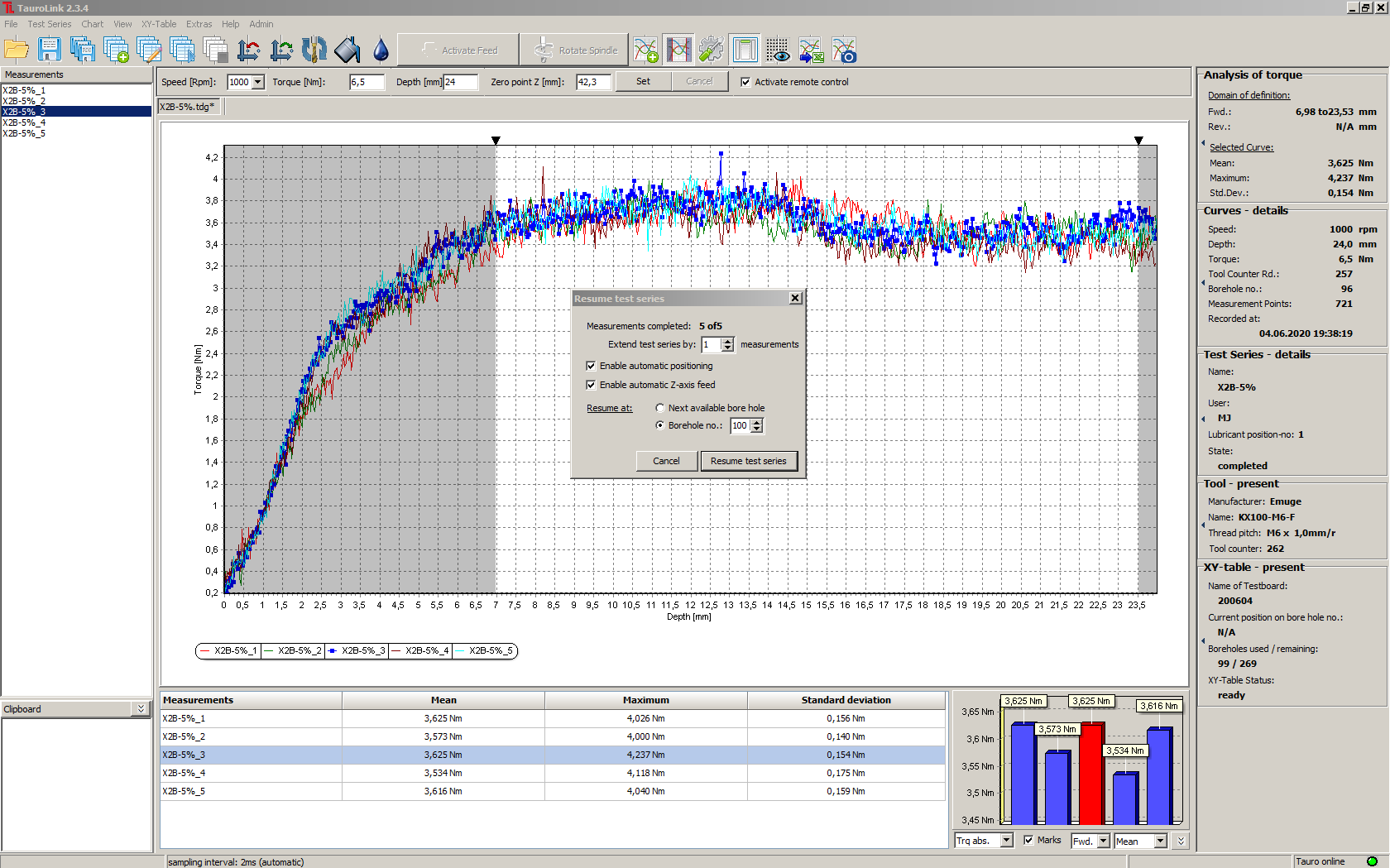

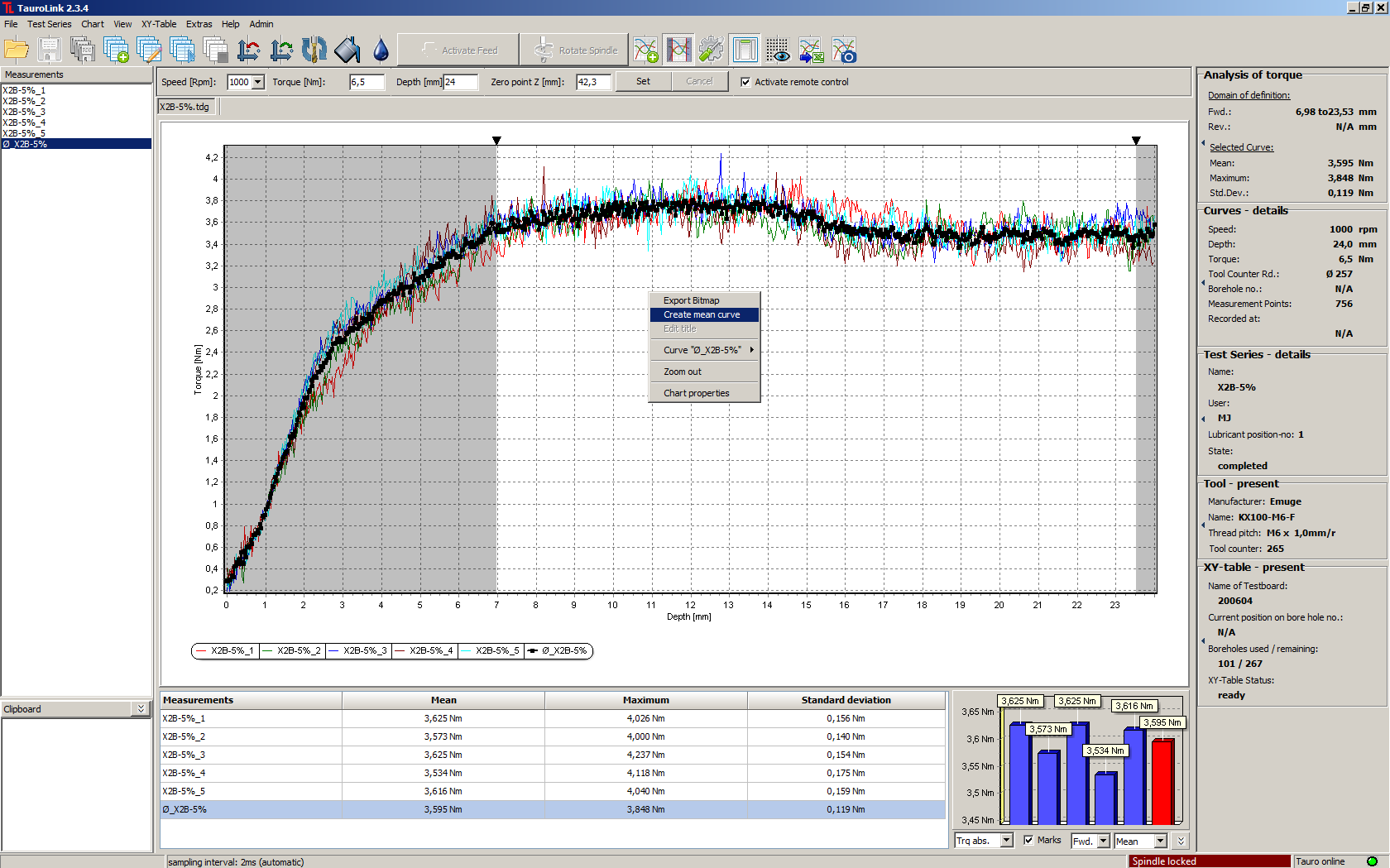

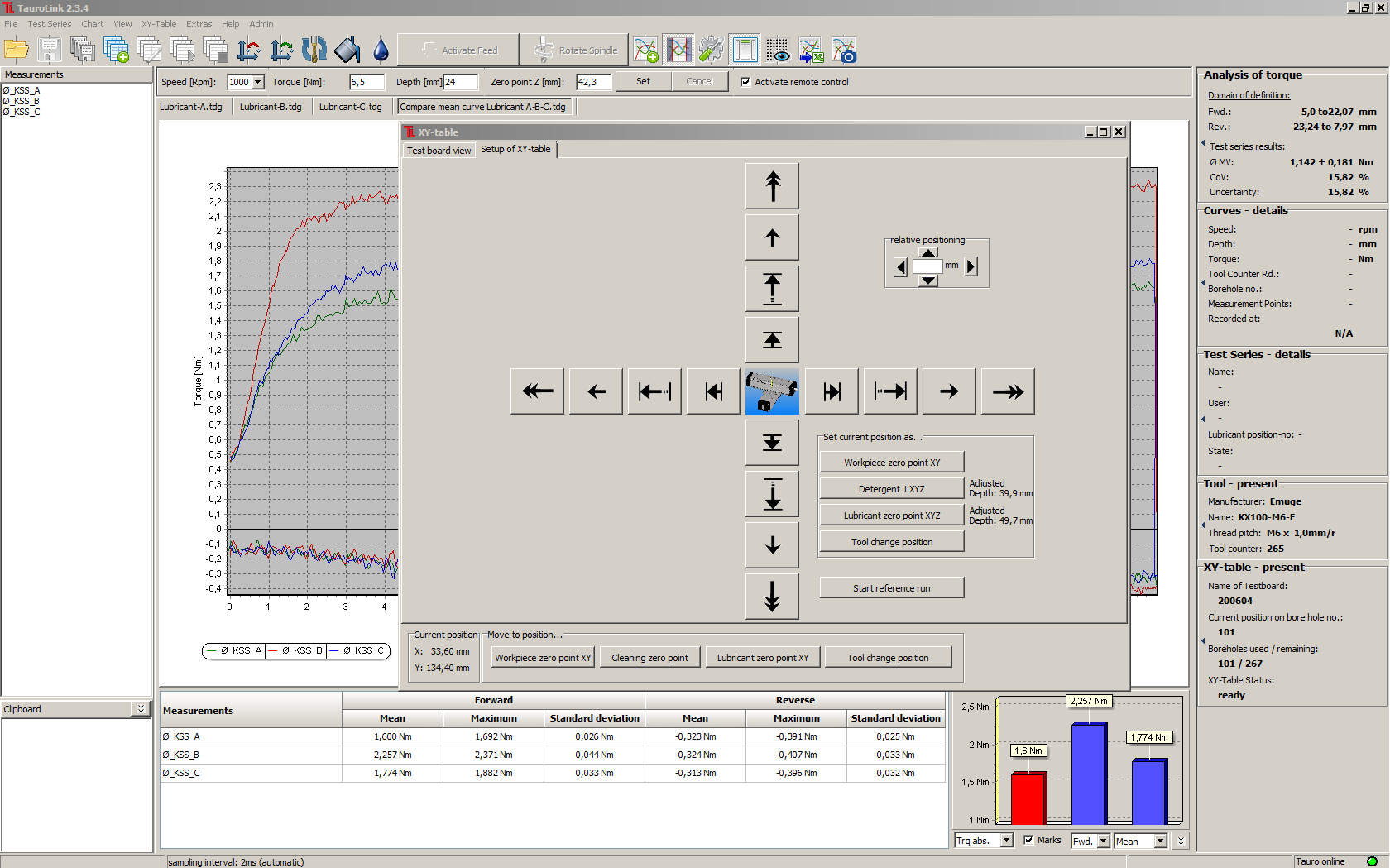

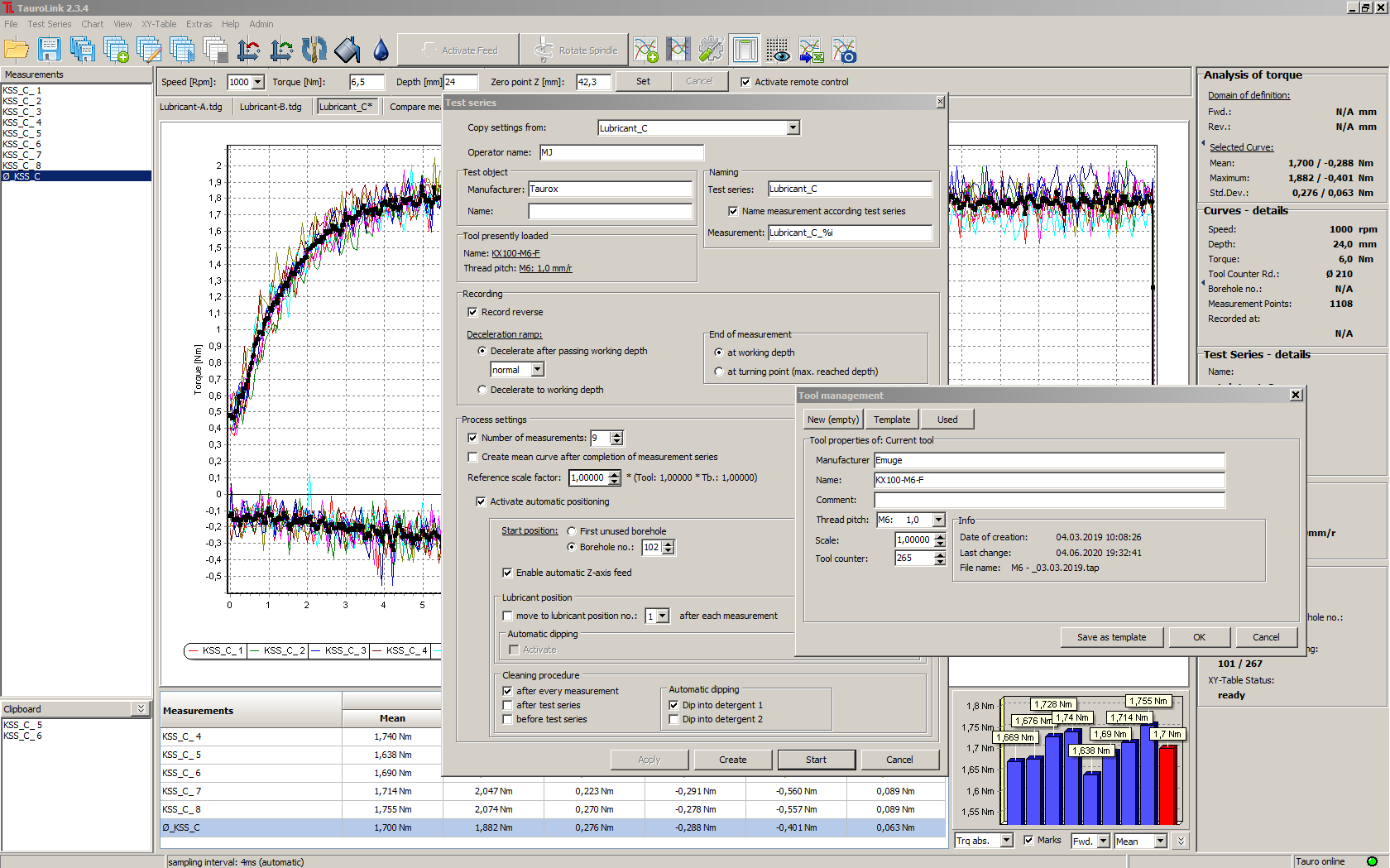

TauroLink Analysis and control software

- Acquisition of process parameters

- Remote control of the Tauro Tribometer

- Acquisition of measured values with 1 ms sampling interval

- Forward and reverse recording in different representations

- Data transmission of measured values via Ethernet

- Presentation, comparison and statistical evaluation of test series in charts

- Evaluation of test series by determined key figures

- Export of measurements and charts (file formats: csv, bmp, png, jpg)

- Safe / open the diagrams

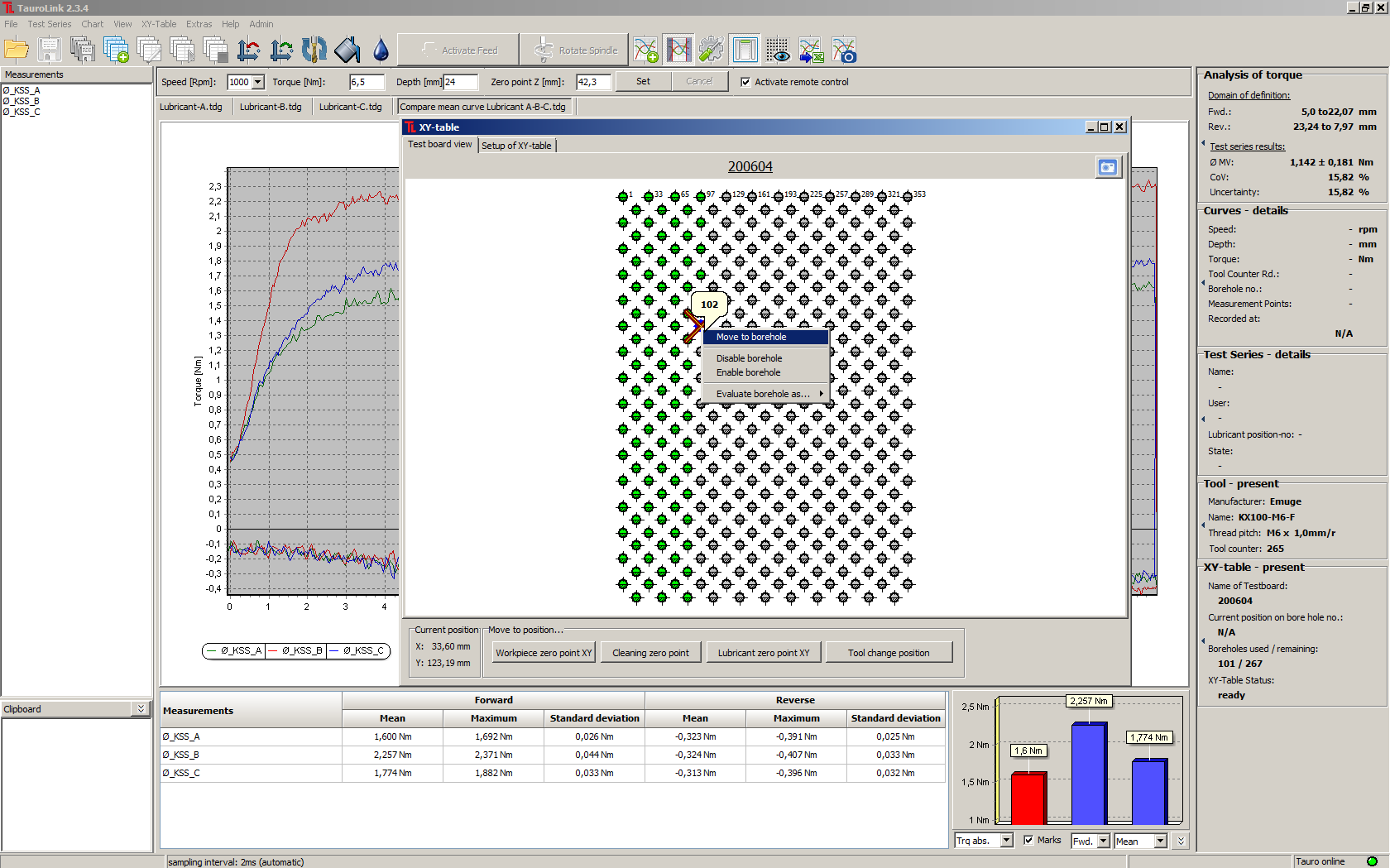

- Automation of test series in conjunction with an XY coordinate table

- Management of test plates

- Management of tools

Minimum system requirements:

- Windows® 7, Windows® 8.0/8.1, Windows® 10 or Windows® 11

- Intel Pentium® 3, or an equivalent x86 CPU, with 1 GHz

- 1 GB RAM

- 100 MB free disk space

- 1 x 100 MBit Ethernet interface

- Monitor resolution 1600 x 900 (WSXGA) to 1920 x 1080 (Full HD)

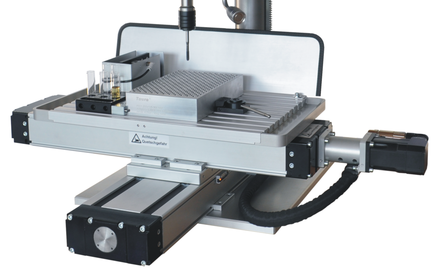

Coordinate table for fully automated test series

- Controlled by TauroLink analysis software

- Driven by AC servo motors with resolver and circulating ball screw

- Range X 300mm / Y 250mm (other ranges on demand)

-

Repeatability +/- 5μm

-

Positioning accuracy +/- 0.01 mm at 20 °C +/- 1 K

- Limit switch and home switch

- Mounting plate with T slot

Cleaning station for automated cleaning of the test tool

- Controlled by TauroLink analysis software

- Tool cleaning with brushes, detergents and circular discharge unit

- Manual or automatic cleaning process

- Cleaning of abrasion and chips

- Easy emptying of cleaning station

Lubricant station for automatic immersion of the test tool

- Automatic immersion process

- Lubricant position selectable in test serie definition